ELECTRIC

ANTI-ICING

Large transport

aircraft that have flush toilets and lavatories have electric powered heating

elements to prevent the drains and water lines from freezing.

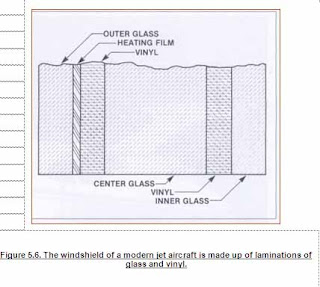

Windshields and cockpit

windows are electrically heated to prevent ice obstructing the vision of the

pilot and the co-pilot. There are two methods of heating these components. One

method uses a conductive coating on the inside of the outer layer of glass in

the laminated windshield, shown in Figure

5.6, and the other method uses tiny

resistance wires embedded inside the laminated windshield. It is heated by

electric current flowing through a conductive film on the inside of the outer

layer of glass.

The windshield of a high-speed jet aircraft is a highly

complex and costly component. For all of the transport category aircraft, these

windshields must not only withstand the pressures caused by pressurization and

normal abuse and flight loads, but they must also withstand, without penetration,

the impact produced by a four-pound bird striking the windshield at a velocity

equal to the airplane's design cruising speed. For a windshield to be this

strong, it is built as a highly complex sandwich, with some of the business jet

windshields about an inch and a half thick, made of three plies of tempered

glass with layers of vinyl between them. The inner surface of the outer ply of

glass is coated with a conductive material through which electric current flows

to produce enough heat to melt off any ice that forms on the windshield. There

are temperature sensors and an elaborate electronic control system to prevent

these windshields from becoming overheated. The windshields are heated not only

to prevent ice, but to strengthen them against bird strikes. When the

windshield is heated, the vinyl layers are less brittle and will withstand an

impact with much less chance of penetration than they will when they are cold.

The engine

intakes of some turboprop aircraft are anti-iced by using electric heating

elements which prevent ice build-up.

No comments:

Post a Comment